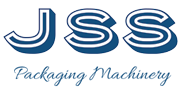

Magnum 4500-BFF Semi-Automatic Case Erector

$9,295.00

• Operating Rate Up to 15 Cases per Minute

• Case Size Capacity 6”-30” L, 6”-24” W, 5”- Unlimited H

• Machine Dimensions 98” L, 41” W, 30”-38” H, 750 Pounds

• Side Belt Drive Random Bottom Flap Folder

Qualified applicants can get approved for financing in as little as seconds with CIT . Applying online is simple. Click the link below to start your application!

Please note that we are not affiliated with CIT Group Inc. and any finance related questions should be directed to their offices.

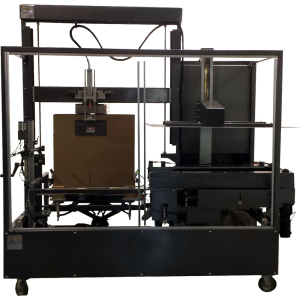

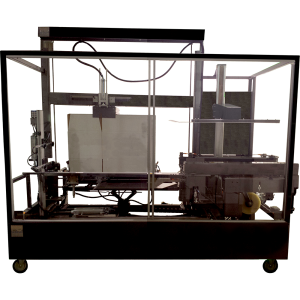

The Magnum 4500 BFF random semi-automatic case erector is a self-adjusting bottom case forming machine with integrated bottom sealer. The design utilizes a precision T-Table, adjustable folding assembly, and reliable side belt drives to provide accurate, consistent case forming and tape application to the bottom of random cases. The machine features dual side belt drives that automatically adjust to the case when a sensor is triggered. The machine is designed to handle cases from 6” to 20” wide, 3” to Unlimited” tall (top flaps open), and 6” to 24” length. The system is designed to operate at 8-12 cases per minute depending on case size in random mode, and up to 20 cases per minute in uniform mode. To allow ergonomic positioning, the pass height can be changed via adjustable legs from 27 inches to 35 inches. Locking casters are included for portability.

The Magnum 4500 Random BFF is offered as an economical productivity-increasing alternative to manually hand forming cases and hand taping, whether filling directly afterwards on a packaging line or stockpiling cases for later filling. Expected improvements in efficiency are typically 3-5 times as many cases output per single operator compared to hand folding in the same time period. In addition, the Magnum 4500 BFF delivers the added benefit of consistent, aesthetically appealing, cost efficient tape application to the bottom of the case.

The primary benefits yielded from the machine are lower labor cost from fewer operators required to produce an equivalent number of cases formed per hour, higher throughput per hour, reduced operator strain from fewer repetitive motions, as well as decreased tape consumption. This results in full return on equipment investment that can be realized in just months of machine usage – not years. The system is designed to work with all Highlight case sealers for a complete packing line solution.

The Magnum 4500 Random BFF includes Highlight’s industry-leading 200 series tape head which will accept any 2-inch carton tape and provide optimum case sealing to the bottom of the case. An optional 3-inch tape head, series 300, is also available for heavy duty applications and is completely interchangeable with the 2” version. Highlight Magnum tape heads are engineered to be the heaviest duty and most reliable tape heads in the industry. The user-friendly design allows for easy tape threading, fewer moving parts for minimal maintenance, and simple built-in adjustability for accommodating virtually any case type.

Additional information

| Brand | Highlight Industries |

|---|---|

| Model | Magnum 4500-BFF |

| Product Type | Semi Automatic Case Erector – Operator Needed |

| Box Type | Random |

| Max Box Height | Unlimited |

| Max Box Length | 30" |

| Max Box Width | 24" |

| Min Box Height | 5" |

| Min Box Length | 6" |

| Min Box Width | 6" |

| Optimal Throughput | 15 cases/min |

| Belt Orientation | Side |

Features

- Automatically folds bottom flaps of cases to increase productivity

- Automatically adjusts to different sized cases

- Magnum 200 Series 2” tape heads standard, 3” optional

- Optional Exit Conveyor

- Locking swivel casters included for easy maneuvering

Options

- Foot Pedal Cycle Trigger. Replaces photo eye for starting the cycle. Ensures operator is positively controlling the belt adjustment; prevents accidental triggers

- Magnum 300 Series 3” Tape Head Upgrade. Replaces standard 2” tape head with 3” wide version. For extra security on heavy duty or large cartons.

- Heavy Duty Flexible Skate Wheel Conveyor. 18” W x 24”-31” Adjustable Height. Extends from 48” to 160” Length, bends around corners. Locking Casters. Other lengths available

- Heavy Duty Box Stand. Height adjustable to allow ergonomic access to case blanks for greater machine output. Adjustable leg lengths for versatile placement. Holds ~50 case blanks (32 ECT)

Specifications

| Specification | Measurement | Comments |

|---|---|---|

| Model | 4500 Random BFF | |

| Type | Side Belt Drive Random Bottom Flap Folder | |

| Tape Head | Magnum 200 Series | |

| Operating Rate | Up to 15 Cases per Minute | |

| Electrical Requirements | 120 Volts, 60 Hz, 10 Amp | |

| Pneumatic Requirements | 80 psi, 4 cfm | |

| Case Minimum Length | 6 inches | |

| Case Maximum Length | 30 inches | |

| Case Minimum Width | 6 inches | |

| Case Maximum Width | 24 inches | |

| Case Minimum Height | 5 inches | |

| Case Maximum Height | Unlimited | |

| Case Belt Speed | 75 feet per minute | |

| Machine Length | 98” Including Conveyor | |

| Machine Width | 41” | |

| Machine Height | Adjustable height from 30 to 38 inches | |

| Machine Pass Height | 27” to 35” adjustable w/locking casters | 22” to 30” with casters removed |

| Machine Weight | 750 pounds | On a pallet |