Magnum 4500 T-Table Case Erector

$10,725.00

- Operating Rate Up to 15 Cases per Minute

- Case Size Capacity 6-30” L, 6-24” W, 5-24” H, 4-75 Pounds

- Automatically adjusts to different sized cases

Qualified applicants can get approved for financing in as little as seconds with CIT . Applying online is simple. Click the link below to start your application!

Please note that we are not affiliated with CIT Group Inc. and any finance related questions should be directed to their offices.

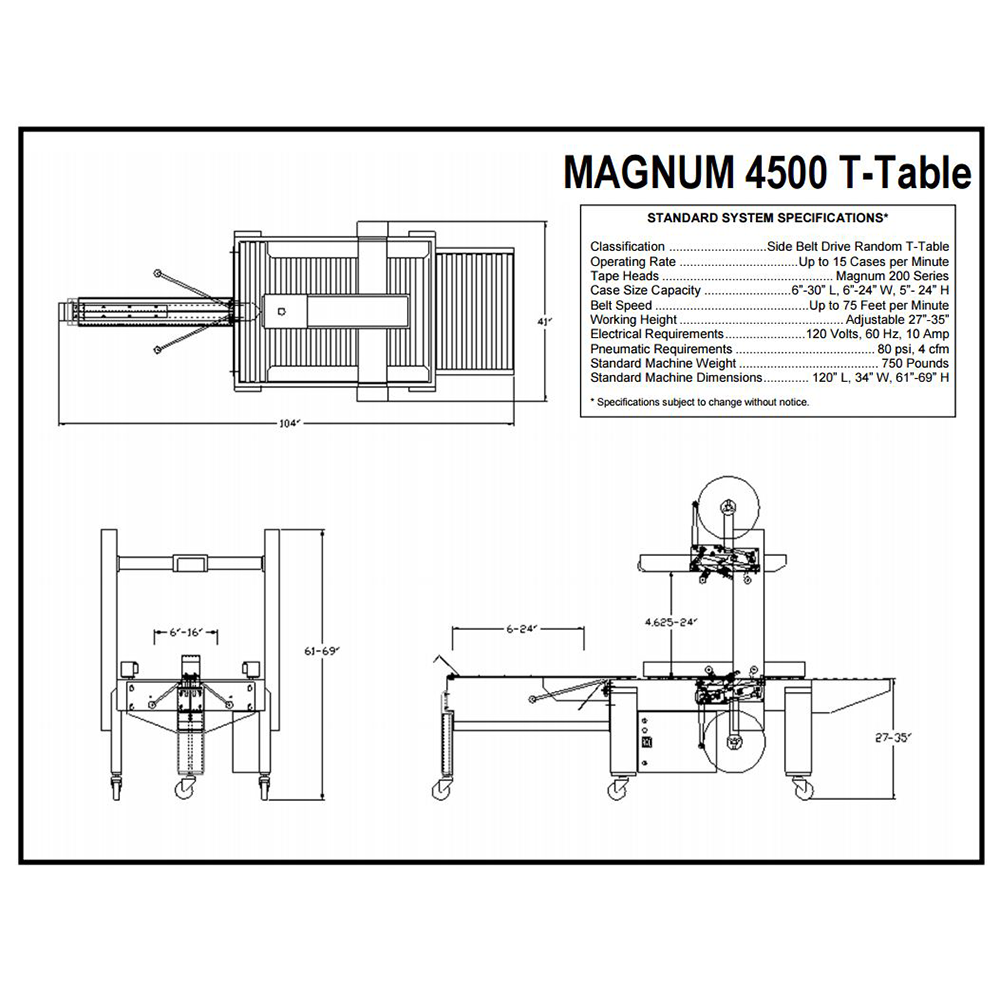

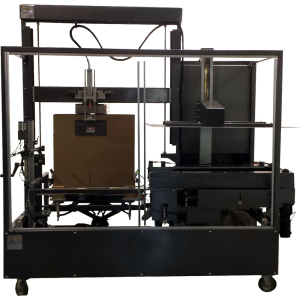

The Magnum 4500 SD-R T-Table is a random semi-automatic side belt drive case former & sealer designed to form the bottom flaps and provide accurate, consistent tape application to random and uniform width, height, and length cases. The Magnum 4500 SD-R features a simple T-Table case forming device to easily fold the bottom flaps of the case. The system’s side belt drives automatically adjust to handle cases from 6” to 24” wide. The top tape head lift assembly automatically repositions according to the case height for cases from 5” to 24” tall. Cases from 6” long to 30” length are smoothly transported on a series of chromed steel rollers capable of handling packages up to 75 pounds. The system is designed to operate at up to 15 cases per minute depending on mode, operator speed, and package dimensions.

The Magnum 4500 SD-R is equipped with a top and bottom Magnum 200 series tape head and will accept any 2 inch case tape, providing optimum case sealing to the top and bottom of the case. An optional 3” tape head is available. Highlight Magnum tape heads are engineered to be the heaviest duty and most reliable tape heads in the industry. The user-friendly design allows for easy tape threading, fewer moving parts for minimal maintenance, and simple built-in adjustability for accommodating virtually any case type.

Dual side belt drives with individual ¼ horsepower gear motors deliver heavy duty performance. Flexible PLC controls with three taping program modes improve reliability and speed. Random Mode 1 is for case forming, packing, and top & bottom sealing which includes a special program that allows increased case throughput. This mode maintains the top tape head assembly at the same relative height as the previous case cycle to reduce machine adjustment time. Random Mode 2 is for random case erecting which keeps the top frame raised to the maximum capacity, allowing the forming & sealing of the bottom of the case only for filling the cases further down the packaging line. The third mode, Uniform, allows for running either of the previous two system modes but increases the output when running larger volumes of uniform cases by fixing the side belts and top frame to the size of the uniform case.

The Magnum 4500 SD-R comes standard with chromed steel conveyor rollers and smooth running precision plastic bearings for easy case movement and long life. Height-adjustable legs from 27 inches to 35 inches are standard with locking casters are included. Optional 18” long x 28” wide entry and exit conveyors are available.

Additional information

| Brand | Highlight Industries |

|---|---|

| Model | Magnum 4500 T-Table |

| Product Type | Semi Automatic Case Erector – Operator Needed |

| Box Type | Random |

| Max Box Height | 24" |

| Max Box Length | 30" |

| Max Box Width | 24" |

| Min Box Height | 5" |

| Min Box Length | 6" |

| Min Box Width | 6" |

| Optimal Throughput | 15 cases/min |

| Belt Orientation | Side |

Features

- T-Table design automatically forms the bottom flaps of the case and holds it down for easy packing

- Automatically adjusts to different sized cases

- Magnum 200 Series 2” tape heads standard, 3” optional

- Optional Exit Conveyor

- Locking swivel casters included for easy maneuvering

Options

- Left Hand Operator Controls. Moves Start/Stop/Reset/Mode control box to left hand side

- Magnum 300 Series 3” Tape Head Upgrade, Pair. For extra security on large or heavy cartons

- Entry -OR- Exit Conveyor Table. 28” wide x 18” long. Chromed Steel Rollers w/ precision plastic bearings for smooth running and long life

- High Speed Belt Upgrade. Upgraded 3PH AC gearmotors & VFD drive for up to 20 cases per minute, depending on case dimensions

- Spare Magnum 200 Series 2” Tape Head. Drop in replacement tape head eliminate down time for tape head maintenance

- HLI # 760067 for 2” tape

- HLI # 760174 for 3” tape

- Spare Parts Kit for Magnum 4500 SD-R. Includes common preventative maintenance machine & tape head items such as belts, fuses, springs, blades, etc.

- HLI # 700563 for 2” tape

- HLI # 700564 for 3” tape

- Heavy Duty Flexible Skate Wheel Conveyor. 18” W x 23”-31” Adjustable Height (28”-40” adjustable height also available). Extends from 48” to 160” Length, bends around corners. Locking Casters

Specifications

| Specification | Measurement | Comments |

|---|---|---|

| Model | Highlight 4500 SD-R T-Table | |

| Type | Side Drive Random | |

| Tape Head | 200 series 2” tape heads | |

| Tape Roll Diameter | 3 inch inside diameter core with up to 16 inches outside diameter | |

| Operating Rate | Up to 15 boxes per minute | Depending on mode and operator speed |

| Electrical Requirements | 120 V, 6OHz, 10 Amps | |

| Case Minimum Length | 6 inches | |

| Case Maximum Length | 30 inches | |

| Case Minimum Width | 6 inches | |

| Case Maximum Width | 24 inches | |

| Case Minimum Height | 5 inches | |

| Case Maximum Height | 24 inches | closed case height in Mode 1 or open case height in Mode 2 (H + ½W) |

| Case Belt Speed | 75 feet per minute | 120 feet per minute optional |

| Machine Length | 46 inches long | Without optional entry or exit conveyor |

| Machine Width | 41 inches | |

| Machine Height | 62 inches standard | Legs set to lowest position |

| Machine Weight | 750 pounds | On a pallet |

| Tape Roll Width | 2 inch | 3 inch optional |

| Air Requirements | 80 PSI @ 4 SCFM | |

| Entry and Exit Conveyor | Optional |