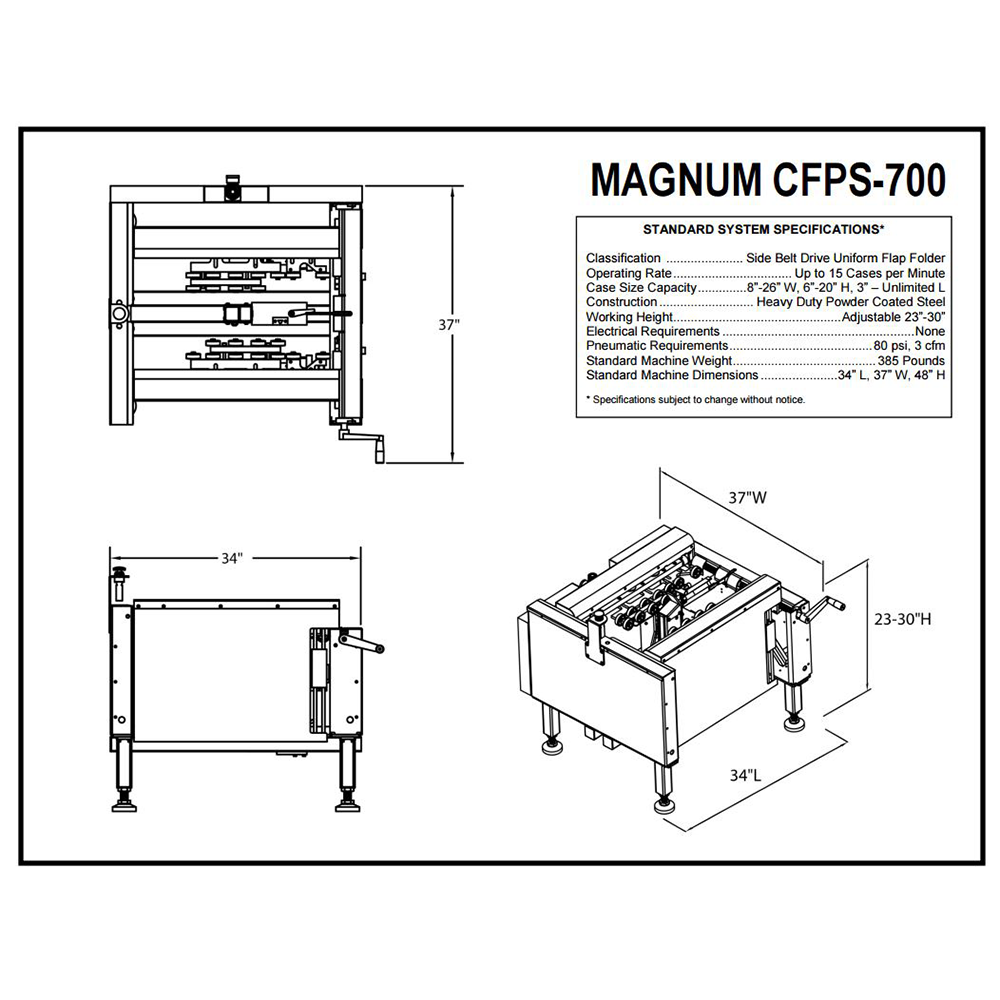

Magnum Model CFPS-700 Semi-Automatic Case Former & Pack Station

$7,899.00

- Speed: Up to 15 Cases per Minute

- Case Size Capacity 8-26” L, 6-20” W, 3”-unlimited H, 0-45 lbs STD; 0-75 lbs optional

- Adjusts to different case sizes easily so you can pack a variety of products

- No Electricity Required

Qualified applicants can get approved for financing in as little as seconds with CIT . Applying online is simple. Click the link below to start your application!

Please note that we are not affiliated with CIT Group Inc. and any finance related questions should be directed to their offices.

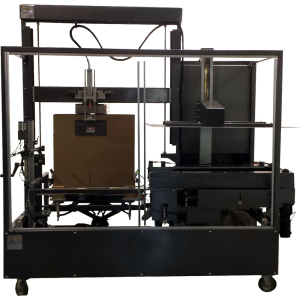

The Magnum 700 (shown with optional casters) is an adjustable semi-automatic carton forming machine and packing station. When an operator places an open, unfolded carton into the machine, all four bottom flaps are automatically folded in proper sequence and the carton is securely held in place for packing. The operator then fills and discharges the packed carton forward from the machine to any carton sealer for taping.

The primary benefit of the machine is the improved production through reduced operator repetitive movements. The machine folds the bottom flaps with the case right-side-up in only two seconds, saving a great amount of time over manually performing the same operation (the operator would otherwise have to flip the carton over, fold all four flaps by hand, then flip the carton right-side-up and place on a table for packing). The machine also combines the benefit of a packaging station which holds the carton in place, which allows the operator to remove their hands while filling the carton with up to 45# of product.

The Magnum 700 is easily adjustable for different case sizes. Turn the side crank handle to accommodate cases from 6” to 20” wide. The case length setting can be changed from 8” to 26” by simply sliding a rear stop into position and securing with a locking handle. No set-up changes are required to accommodate case heights from 3” to 24” or higher.

Additional information

| Brand | Highlight Industries |

|---|---|

| Model | CFPS-700 |

| Product Type | Forming and Pack Station |

| Box Type | Random |

| Max Box Height | Unlimited |

| Max Box Length | 26" |

| Max Box Width | 20" |

| Min Box Height | 3" |

| Min Box Length | 8" |

| Min Box Width | 6" |

| Optimal Throughput | 8+ cases/min |

Features

- Simple and efficient operation allows cases to be formed as they are needed and triples operator efficiency

- Interfaces with any Highlight carton sealer for flexibility and maximized productivity

- Adjusts to different case sizes easily so you can pack a variety of products

- Full pneumatic operation eliminates the need for electricity, sensors, and a PLC

- Pre-opens major flaps then folds all flaps sequentially for reliable jam free operation

- Erected cases are supported on rollers for smooth case ejecting

- Three box contact points are used to start cycle, ensuring operator efficiency

- Simple crank handle and locking knob adjustment provide quick size changeover

- All pneumatic operation eliminates the need for electricity, sensors, and a PLC

- Wedge rollers are engineered to hold the folded case securely for easy packing

- Easily integrated with any Magnum Case Sealer

- Construction: Heavy duty corrosion resistant steel construction Formed steel sheet metal covers

- Hard wearing powder coated finish: Designed to minimize maintenance

Options

- Locking Casters, set of 4. Replaces leveling feet. Includes shorter Leg Mounts to account for difference in height between feet & casters. Changes pass height range to 25” ~ 31”

- Heavy Product Lift / Support Cylinder Upgrade. Allows packing of products up to 75 pounds

- Pneumatic Case Eject Assembly. Pushes the packed carton from the machine into a carton sealer Simple operator push button control. Reduces operator strain. *Must specify right hand or left hand operation. *Minimum 5”H cases required to use this feature

- Rear Top Minor Flap Folding Device to Pneumatic Case Eject Assembly*. Attaches to the Case Eject Assembly pusher arm. For use with a Magnum 2300 w/ 3 flap folding device and extended drive belts. Creates automatic 4 top flap folding as the case is ejected into the Magnum 2300 3-flap folder. *Maximum 20” L cases required to use this feature

- Roller Lock Up Switch. Maintains the major flap supporting rollers in the horizontal position. Ideal for tray of OPF style cases

- Tilting Frame Upgrade. Allows the Magnum 700 to tilt towards the operator for easier case loading. Ideal for tall, difficult to load cases or unstable products that cannot be loaded vertically. Press lever to tilt the machine for case loading and packing. Reverse the lever to upright the machine and discharge the case. *Must specify desired pass height (floor to bottom of case ht) and right hand or left hand operation

- Heavy Duty Box Stand. Allows ergonomic access to case blanks for higher machine output. Holds ~50 case blanks (32 ECT)

Specifications

| Specification | Measurement | Comments |

|---|---|---|

| Model | Magnum 700 | Case Former & Packing Station |

| Type | Semi-Automatic | |

| Tape Head | N/A | |

| Tape Roll Diameter | N/A | |

| Operating Rate | Up to 8+ boxes per minute | Depending on mode and operator speed |

| Case Belt Speed | N/A | |

| Tape Roll Width | N/A | |

| Case Minimum Length | 8 inches | |

| Case Maximum Length | 26 inches | (20 inches with rear top minor flap folding option) |

| Case Minimum Width | 6 inches | |

| Case Maximum Width | 20 inches | |

| Case Minimum Height | 3 inches | (5 inches with pneumatic case eject) |

| Case Maximum Height | Unlimited by machine | determined by what is reasonable for operator to pack |

| Case Minimum Weight | 0 Pounds | |

| Case Maximum Weight | 75 Pounds | |

| Electrical Power | N/A | |

| Machine Length | 36″ | |

| Machine Width | 38” | |

| Machine Height | Adjustable height from 23 to 32 inches | |

| Machine Weight | 385 pounds | On a pallet (base Model) |

| Air Requirements | 80 PSI @ 3 SCFM | |

| Entry and Exit Conveyor | N/A | Interfaces with carton sealer |