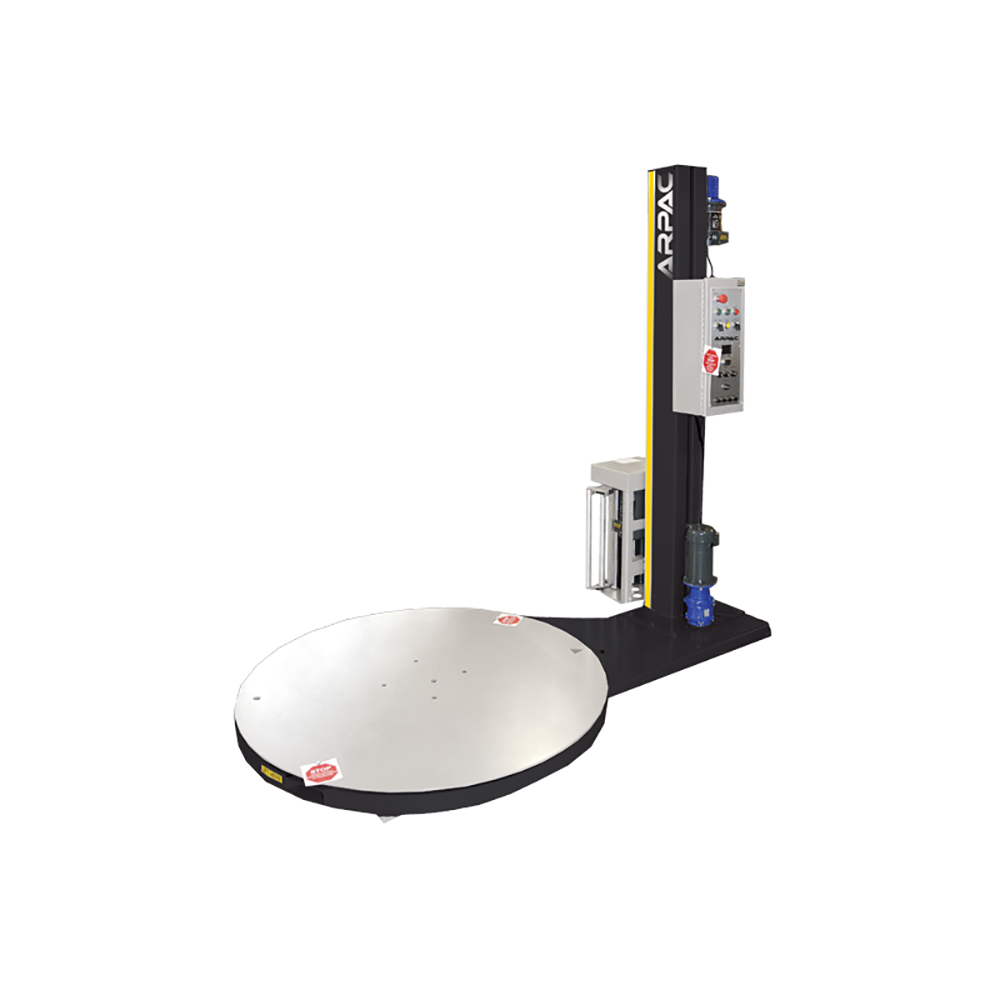

Pro Series Semi-Automatic Low Profile Turntable Stretch Wrapper

$11,699.00

- Up to 12 RPM rotating table can deliver 25-40 loads per hour

- EZ-Load® dispenser for 20-inch film (standard)

- 81” max load height (standard)

- 60 in. Diameter turntable size (standard)

Qualified applicants can get approved for financing in as little as seconds with CIT . Applying online is simple. Click the link below to start your application!

Please note that we are not affiliated with CIT Group Inc. and any finance related questions should be directed to their offices.

The ARPAC Pro-Series low profile turntable pallet wrapper, is a robust wrapper designed, manufactured and supported to offer trouble free operation. The new PRO-SERIES® enjoys the reputation of being one of the most cost-effective semi-automatic machines on the market today. A new ergonomic sturdy design, with chains enclosed in the tower frame, ensures safer operation.

The PRO-SERIES® can be customized to suit your material handling requirements with extended towers for taller loads and split frames for odd-sized larger loads.

The PRO-SERIES® is part of a robust line of stretch wrapping equipment designed to maximize stretch film usage while ensuring the very best load unitization. All ARPACSTRETCHTM equipment is constructed with heavy-duty reinforced structural steel, and finished with non-corrosive Steel-It paint, to guarantee years of reliable wrapping. The PRO-SERIES® is manufactured in the USA.

Additional information

| Brand | Arpac |

|---|---|

| Model | Pro Series Low-Profile |

| Product Type | Semi-Automatic Low Profile Stretch Wrapper |

| Standard Load Dimensions | 85" Diagonal |

| Standard Turntable Weight Capacity | 4000 pounds |

| Standard Stretch Wrap Height | 81" |

| Max Loads An Hour | 25-40 |

Features

- Adjustable top and bottom illuminated LED wrap counters from 1-7

- Magnetic proximity switches in place of mechanical limit switches

- Cycle pause feature

- Top over wrap control feature (TOC) Allows the operator to adjust the amount of film over wrap above the top of the pallet. This eliminates any slide or screwdriver adjustment of the photo eye.

- Electronic film tension adjustment control on control panel

- Manual jog control for turntable

- Upgraded photo eye for automatic load height sensing

- Heavy-duty, welded steel construction (no plastic panels) designed for long life

- Environmentally friendly Powder Coated paint

- Variable turntable speed using 1/2 HP, 90VDC motor with ANSI 50 chain drive system

- Up to 12 RPM rotating table can deliver 25-40 loads per hour

- EZ-Load® film pre-stretch dispenser for 20-inch film rolls

- Dual anti-static film rollers with manufacturer’s lifetime warranty

- Film pre-stretch capability from 150% to 300% stretch factor (200% standard)

- Variable carriage speed up to 21 feet per minute

- 1/2 HP, 90VDC motor with ANSI 40 chain lift drive

- Dancer bar variable corner compensation

- Electronic film tension adjustment control

- Allen-Bradley power, control, and safety components used throughout

- Allen-Bradley MicroLogix PLC

- UL/CSA approved components

Options

- ACCESS RAMP (STANDARD):

- USED FOR HAND PALLET JACK LOADING TO LOW PROFILE MACHINES

- ACCESS RAMP (72” TURNTABLE):

- USED FOR HAND PALLET JACK LOADING TO LOW PROFILE MACHINES

- 48” RAMP EXTENSION (STANDARD):

- USED FOR ELECTRIC PALLET JACK LOADING TO LOW PROFILE MACHINES

- 48” RAMP EXTENSION (72” TURNTABLE):

- USED FOR ELECTRIC PALLET JACK LOADING TO LOW PROFILE MACHINES

- EXTENDED FILM TOWER: USED FOR WRAPPING TALLER LOADS EXCEEDING STANDARD MACHINE CAPABILITY. STANDARD MACHINE WRAPS UP TO 74” (HP) & UP TO 84” HIGH (LP). REDUCE UPTO 3” FOR W-N-W MODELS

- 12” EXTENDED TOWER

- 24” EXTENDED TOWER (KNOCKED DOWN TOWER, SOME ASSEMBLY REQUIRED)

- 36” EXTENDED TOWER (KNOCKED DOWN TOWER, SOME ASSEMBLY REQUIRED)

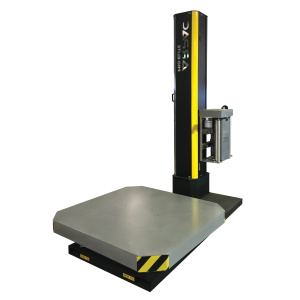

- TURNTABLE UPGRADES: USED FOR SUCH APPLICATIONS WHERE A LARGER LOAD DIAGONAL IS REQUIRED.

- HIGH PROFILE (50 x 50, 4000LBS TURNTABLE STANDARD)

- 50 x 90 TURNTABLE, INCLUDES SPLIT FRAME

- UPGRADE TO 6000 LBS CAPACITY (HIGH PROFILE60” SQ. TURNTABLE)

- SPLIT FRAME CONSTRUCTION IF NOT INCLUDED (THIS FEATURE CAN BE APPLIED TO THE HIGH-PROFILE OPTIONS ABOVE)

- LOW PROFILE (60” ROUND, 4000LBS, TURNTABLE STANDARD)

- 60” ROUND TURNTABLE & 5000 LBS LOAD CAPACITY UPGRADE, INCLUDES SPLIT FRAME

- 72” ROUND TURNTABLE & 6000 LBS LOAD CAPACITY UPGRADE, INCLUDES SPLIT FRAME

- 90” ROUND TURNTABLE & 6000 LBS LOAD CAPACITY UPGRADE, INCLUDES SPLIT FRAME

- SPLIT FRAME CONSTRUCTION FOR STANDARD TURNTABLE

- 12” EXTENDED BASE FRAME USED FOR OVERSIZED PALLETS (USED FOR OVERSIZE LOADS, ONLY AVAILABLE ON SPLIT FRAME)

- SPLIT BASE OPTIONS

- 8FT CABLE BETWEEN TURNTABLE AND TOWER

- 12FT CABLE BETWEEN TURNTABLE AND TOWER

- AFTD (AUTOMATIC FILM TEAR DEVICE): THIS DEVICE AUTOMATICALLY TEARS FILM AT THE END OF THE CYCLE ELIMINATING SHARP OBJECTS FROM BEING USED BY OPERATORS TO CUT FILM

- WRAP-N-WEIGH: ADDS SCALE PCKAGE TO TURNTABLE, INCLUDES SPLIT BASE

- STANDARD 4 LOAD CELL WITH DIGITAL READOUT

- OPTIONAL PRINTER FOR LABELS WITH WEIGHT INFORMATION

- WRAP-N-WEIGH ACCESS RAMP (60” TURNTABLE): USED FOR HAND PALLET JACK LOADING TO LOW PROFILE WNW MACHINES

- WRAP-N-WEIGH ACCESS RAMP (72” TURNTABLE): USED FOR HAND PALLET JACK LOADING TO LOW PROFILE WNW MACHINES

- 48” WNW RAMP EXTENSION (60” TURNTABLE): USED FOR ELECTRIC PALLET JACK LOADING TO LOW PROFILE WNW MACHINES

- 48” WNW RAMP EXTENSION (72” TURNTABLE): USED FOR ELECTRIC PALLET JACK LOADING TO LOW PROFILE WNW MACHINES

- OPTIONAL INPUT VOLTAGES:

- 200 V – 480 V / 60 HZ

- 200 V – 480 V / 50 HZ

- CYCLE COUNTER: A DEVICE THAT COUNTS THE ACTUAL CYCLES OF THE MACHINE (RESETTABLE)

- MANUAL ROPING GUIDE (ADJUSTABLE): USED FOR TURNING FULL WEB INTO A ROPE OR BAND

- DARK READ EYE: USED FOR SENSING DARK OR REFLECTIVE LOADS

- COLD PACK: USED WHERE THE PALLET WRAPPER WILL BE EXPOSED TO TEMPS AS LOW AS 32 DEG FAHRENHEIT

- FREEZER PACK: USED WHERE THE PALLET WRAPPER WILL BE EXPOSED TO TEMPS FROM 31 TO -15 DEGREES FAHRENHEIT

- CONTROL PANEL OPTIONS

- NEMA 4: CONTROL CABINETS FOR MOIST ENVIRONMENTS. NOT WASHDOWN

- NEMA 12: CONTROL CABINET FOR DUSTY ENVIRONMENTS

- TOP PLATEN (FREE STANDING): USED FOR TALL, LIGHT, OR UNSTABLE LOADS. THIS DEVICE APPLIES PRESSURE TO THE TOP OF THE SKID STABILIZING THE LOAD FOR ROTATION. STANDARD 24” DIAMETER PAD

- 12” EXTENSION ON TOP PLATEN MAST

- 24” EXTENSION ON TOP PLATEN MAST

- 36” EXTENSION ON TOP PLATEN MAST

- 36” DIAMETER PAD UPGRADE

- HIGH PROFILE (50 x 50, 4000LBS TURNTABLE STANDARD)

Specifications

| Specification | Measurement | Comments |

|---|---|---|

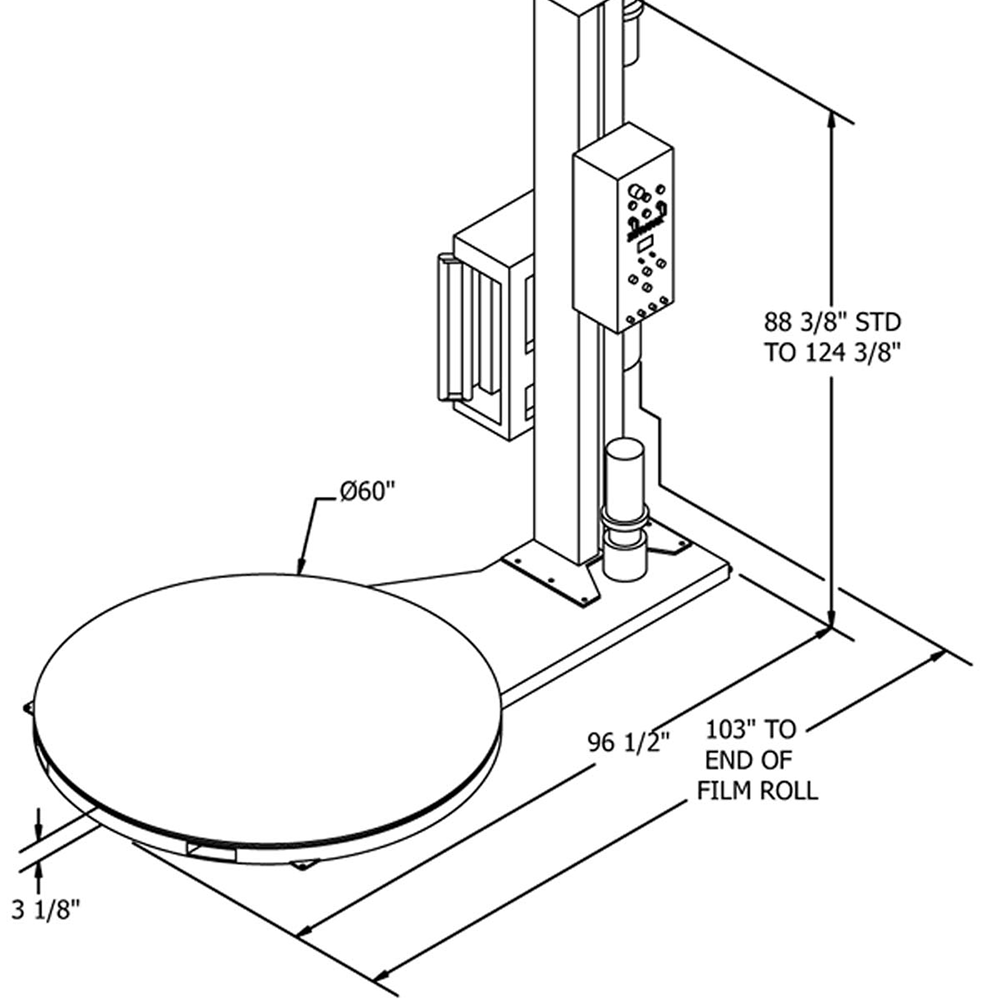

| Turntable Size – Low Profile | 60 in. Diameter (standard) | 3/8” steel plate turntable top. |

| Max. Load Diagonal Clearance | 85 in. (standard turntable) | |

| Max. Load Weight Capacity | 4000 pounds (standard) | Multi-point caster support |

| Turntable Rotation Speed | Up to 12 RPM | ½ HP, 90VDC motor with ANSI 50 chain drive system |

| Loads Wrapped per Hour | 25 to 40 | Depending on load size and film width |

| Standard Load Height – Low Profile | 81 inches | |

| Machine Height– Standard tower | 88.125 in | Measured from floor to top of machine (will require higher clearance when machine is lifted and moved by fork truck) |

| Total Machine Length | 103 in | From end of turntable to end of film roll. Dimension will change with optional turntables. |

| Machine Width | 60 in | Dependent on turntable. |

| Shipping Weight (std) | 1,525 pounds | May be higher with options. |

| Electrical Power | 120VAC, 60hz., 1phase, 10A | Recommend dedicated 20A circuit. |

| Compressed Air | None |